Electronic Manufacturing and Engineering

After the PCB assemblies are fully assembled, these are installed in their enclosures. Final inspection allows accepted units to be packaged and shipped to the customer. These are electrically UNTESTED products.

At the customers test bench 99 units out of every 100 will pass electrical testing. The 1% that fail may have failed or dead components.

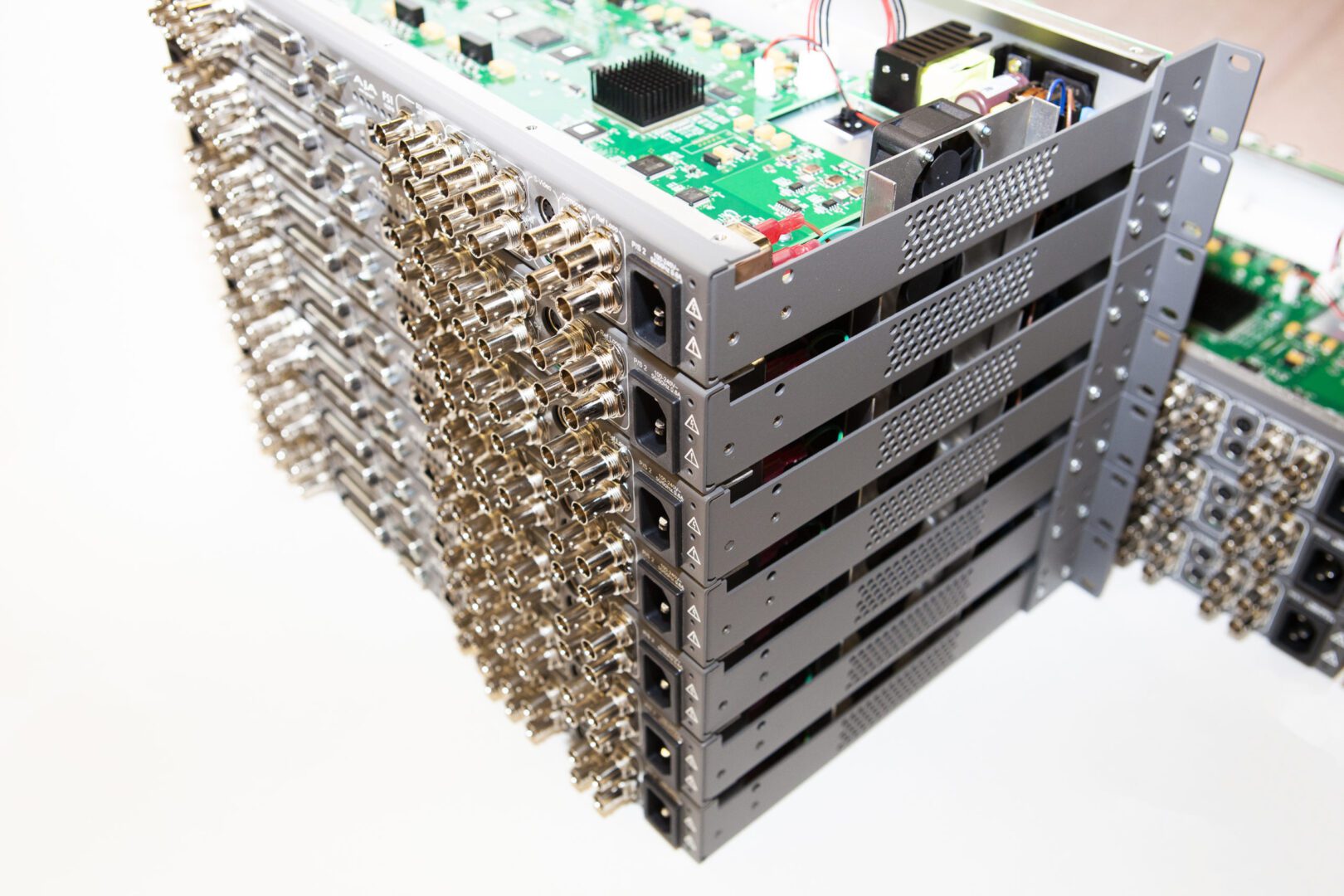

Finished Products

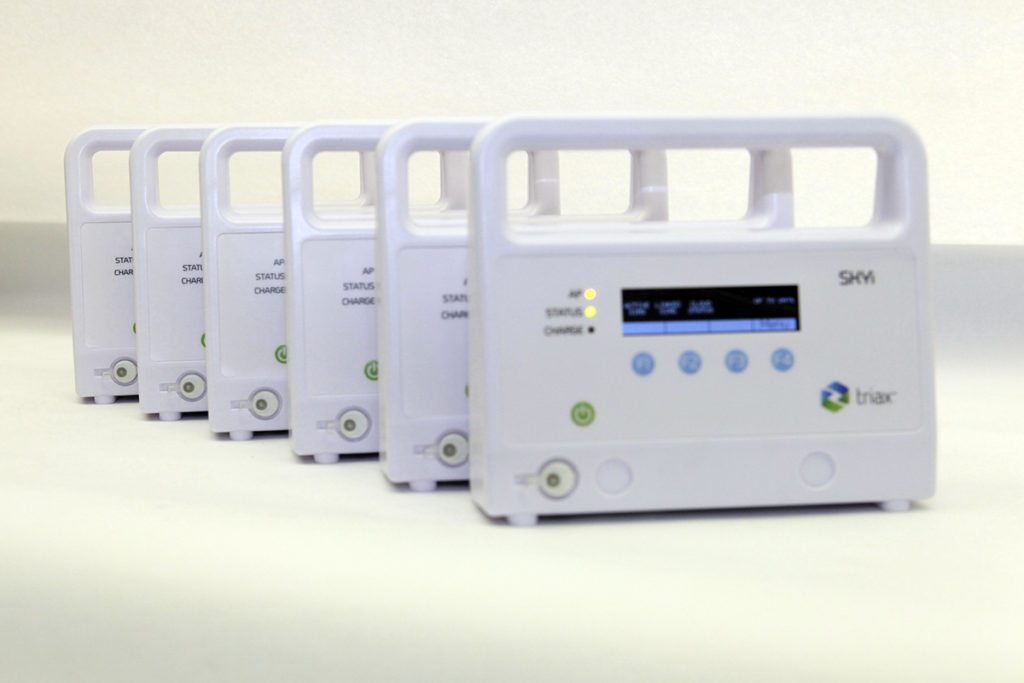

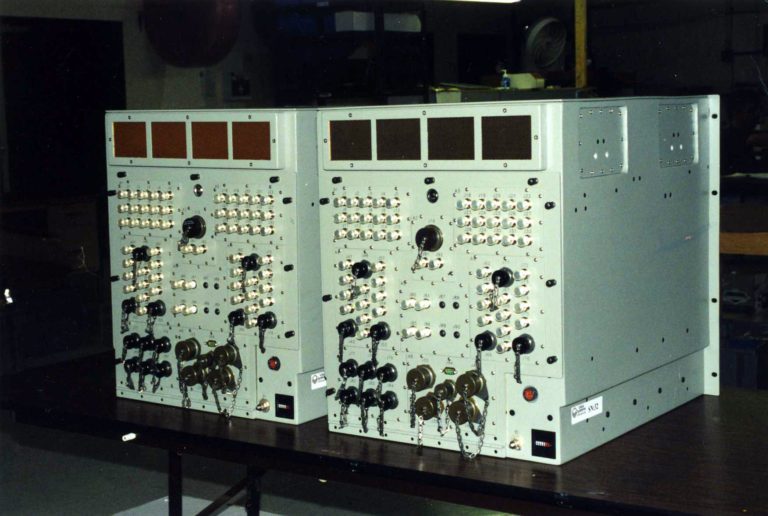

Vital Systems produces vital safety devices for the Rail industry. Product shown above is made in different configurations for US and European markets. This and some other safety devices were design, engineered and and delivered to the industry.

This safety device was developed by our customer and produced at Vital Systems. Product electronics were assembled tested and integrated and after burn-in these units were delivered to the customer.

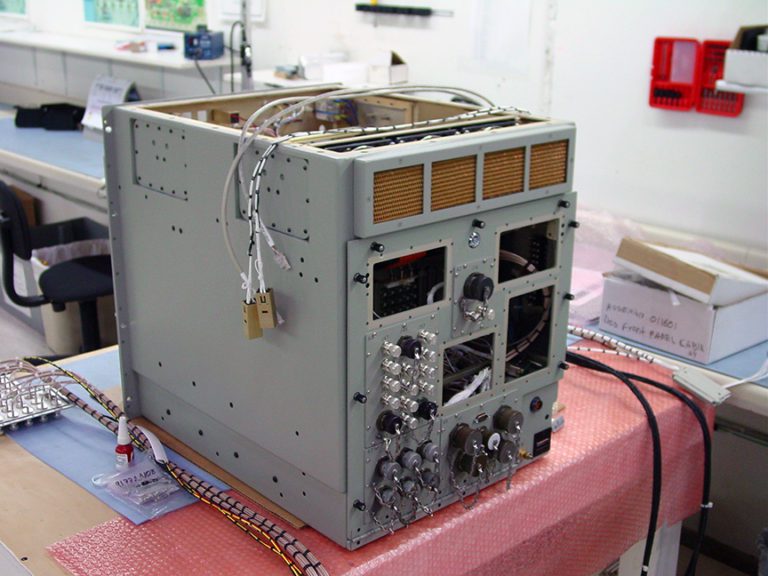

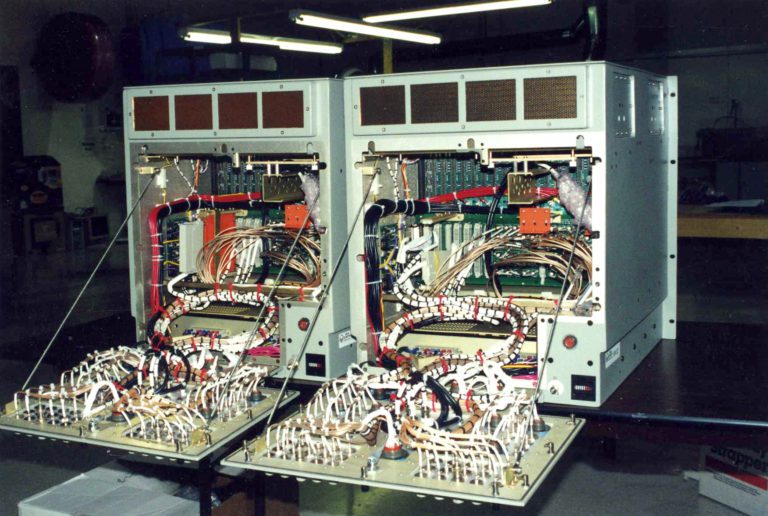

NASA & Military Products

Since 1986 Vital Systems has engineered and produced electronics for higher reliability applications such as NASA’s International Space Station. US Navy’s Ship Self-Defense System. US Air Force’s communication antenna, and for several others DoD contractors, including Boeing, Lockheed, Raytheon and others. This large chassis was engineered at Vital Systems for manufacturability. It was then produced for the Navy’s Ship Self Defense System for over a decade, fulfilling the requirements.

The Vital Difference

Vital Systems offers what few companies offer: the finest in electronic manufacturing and the experience to help our customers design new products. With our manufacturing background we design new products for manufacturability and with it comes reliability while at the same time keeping the manufacturing cost low.